CPVC Pipes & Fittings

CPVC PIPES

Finolex CPVC Pipes our premium offering manufactured using high grade raw material and the latest technology, making these ideal for hot and cold-water applications. These pipes can withstand higher temperatures as compared to any other plastic piping system.

We recommend the use of our CPVC pipes for water supply and distribution in both domestic and industrial applications, and for solar and electric water heaters.

Finolex CPVC pipes are lightweight, non-corrosive and long lasting, which make them a good substitute for GI & conventional pipes. These pipes are manufactured using lead free compounds. Hence they are safe, health and environment friendly.

Our stringent quality assurance approach across all stages of manufacturing gives this product a high degree of reliability, making Finolex CPVC a preferred choice of leading MEP consultants, architects, builders, plumbing contractors,plumbers, and quality-conscious people across the country.

The CPVC plumbing pipes are available in sizes from 15mm (1/2") to 50mm (2") conforming to IS 15778 in SDR 11 & 13.5 classes. CPVC pipes are also available in ‘Iron Pipe Size’ (IPS) from 65mm (2 1/2") to 150mm (6") in Schedule 40 and Schedule 80 series which meet the requirements of ASTM F 441. These pipes are plain ended and are available in standard lengths of 3 and 5 meters with various pressure ratings.

Although these pipes have similar physical properties, the classes differ in wall thickness and therefore at any given temperature their pressure ratings will differ. Finolex CPVC pipes are recommended for water temperature up to 82°C.

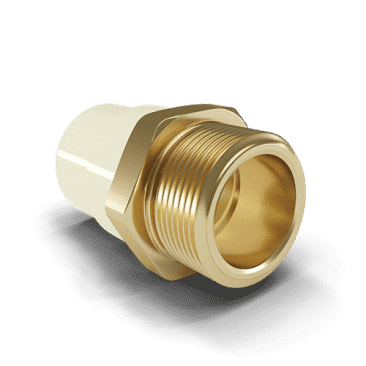

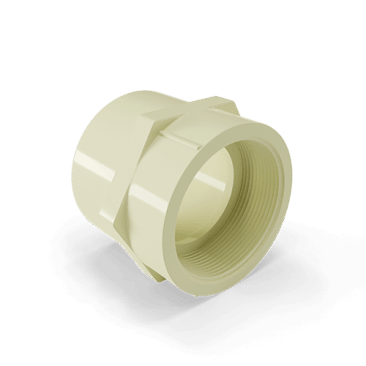

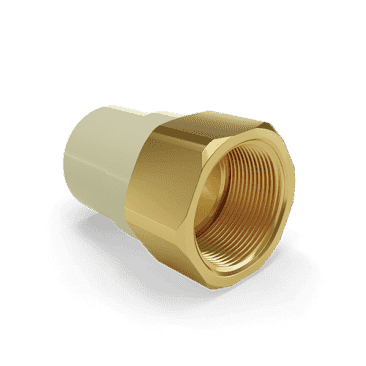

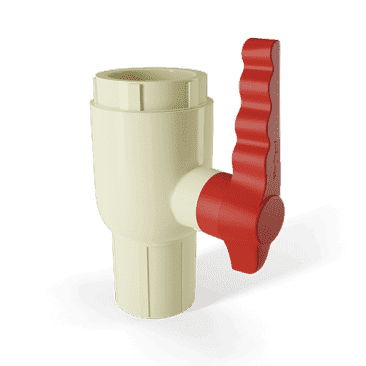

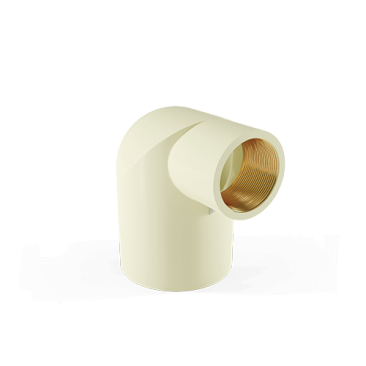

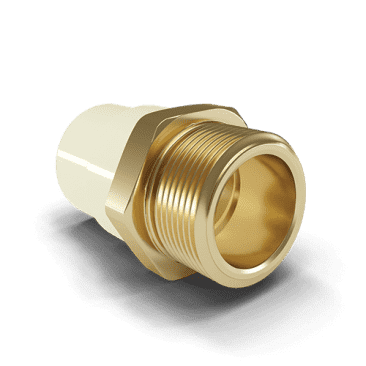

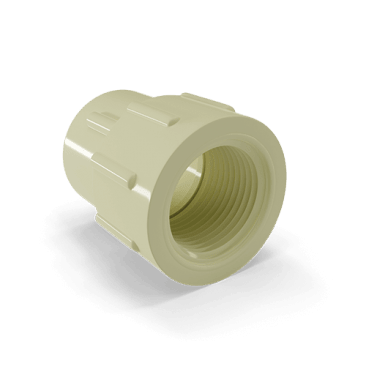

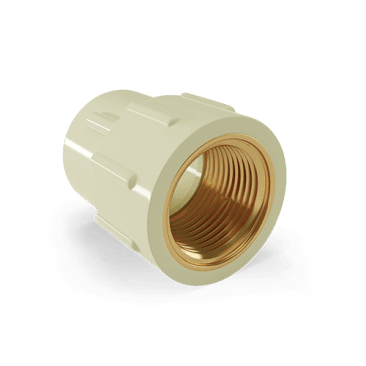

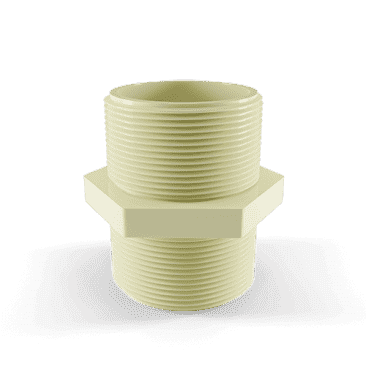

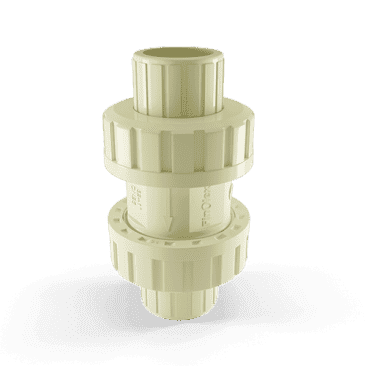

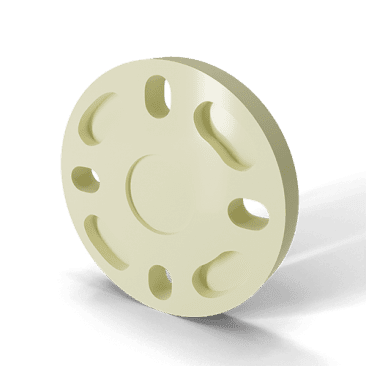

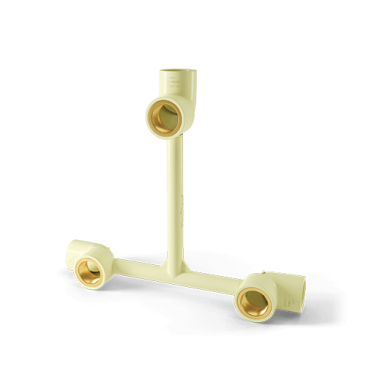

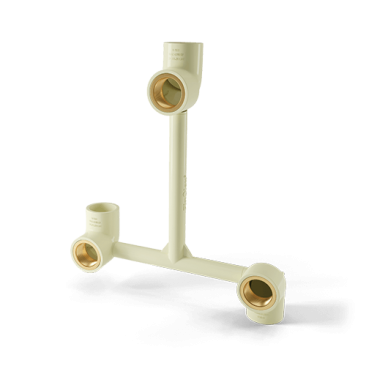

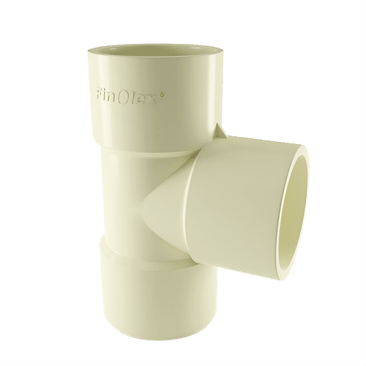

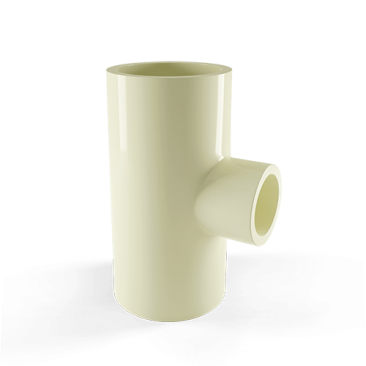

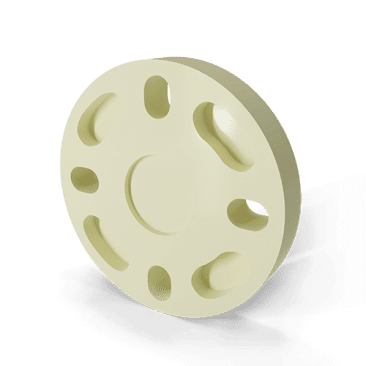

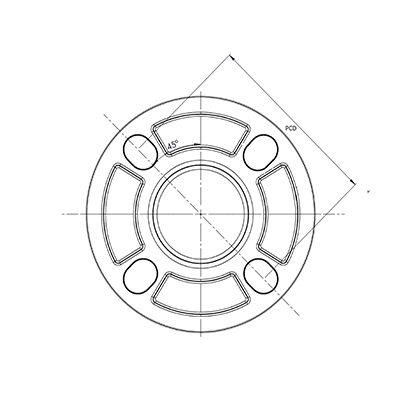

CPVC FITTINGS

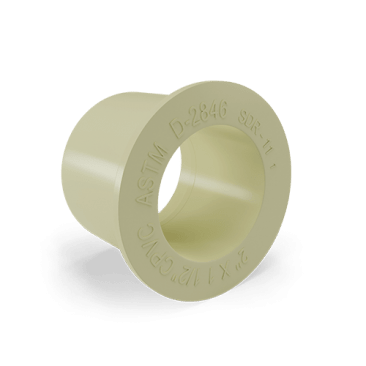

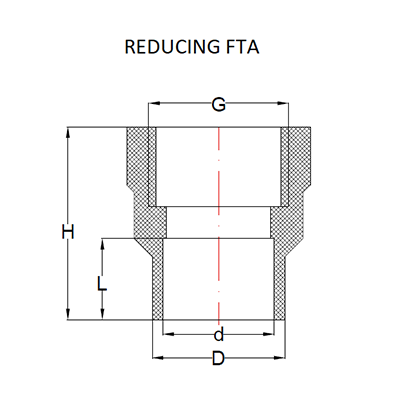

CPVC fittings are available in sizes from 15 mm (1/2”) to 50 mm (2”) and meet the requirement of ASTM D 2846 in Copper Tube Sizing (CTS). CPVC fittings from 65 mm (2.1/2”) to 150 mm (6”) in Schedule 40 and Schedule 80 are manufactured as per ASTM F 438 & ASTM F 439 respectively.

Application

Finolex CPVC pipes are suitable for hot and cold water distribution systems for indoor and outdoor applications. Note: Not suitable for compressed air and gases.

Technical Details

PRESSURE DERATING FACTORS AT WORKING TEMPERATURES

| Working Temperature | Pipe Derating factor | |

| In ℉ | In ℃ | Finolex CPVC Pipes |

| 73-80 | 23-27 | 1.00 |

| 90 | 32 | 0.91 |

| 100 | 38 | 0.82 |

| 120 | 49 | 0.65 |

| 140 | 60 | 0.50 |

| 160 | 71 | 0.40 |

| 180 | 82 | 0.25 |

JOINTING

|

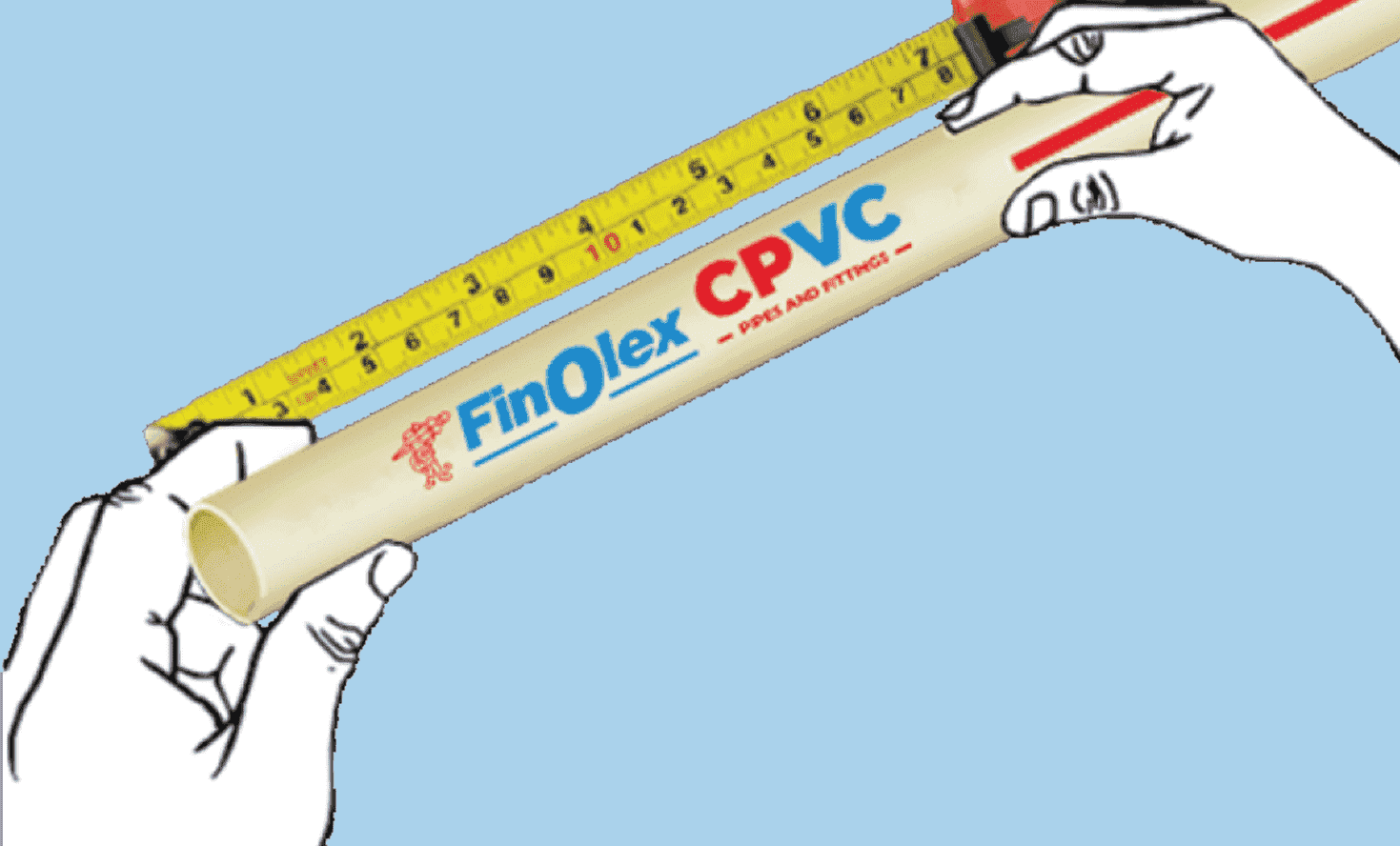

1. Measuring : Measure the required length of pipe and marking done. |

|

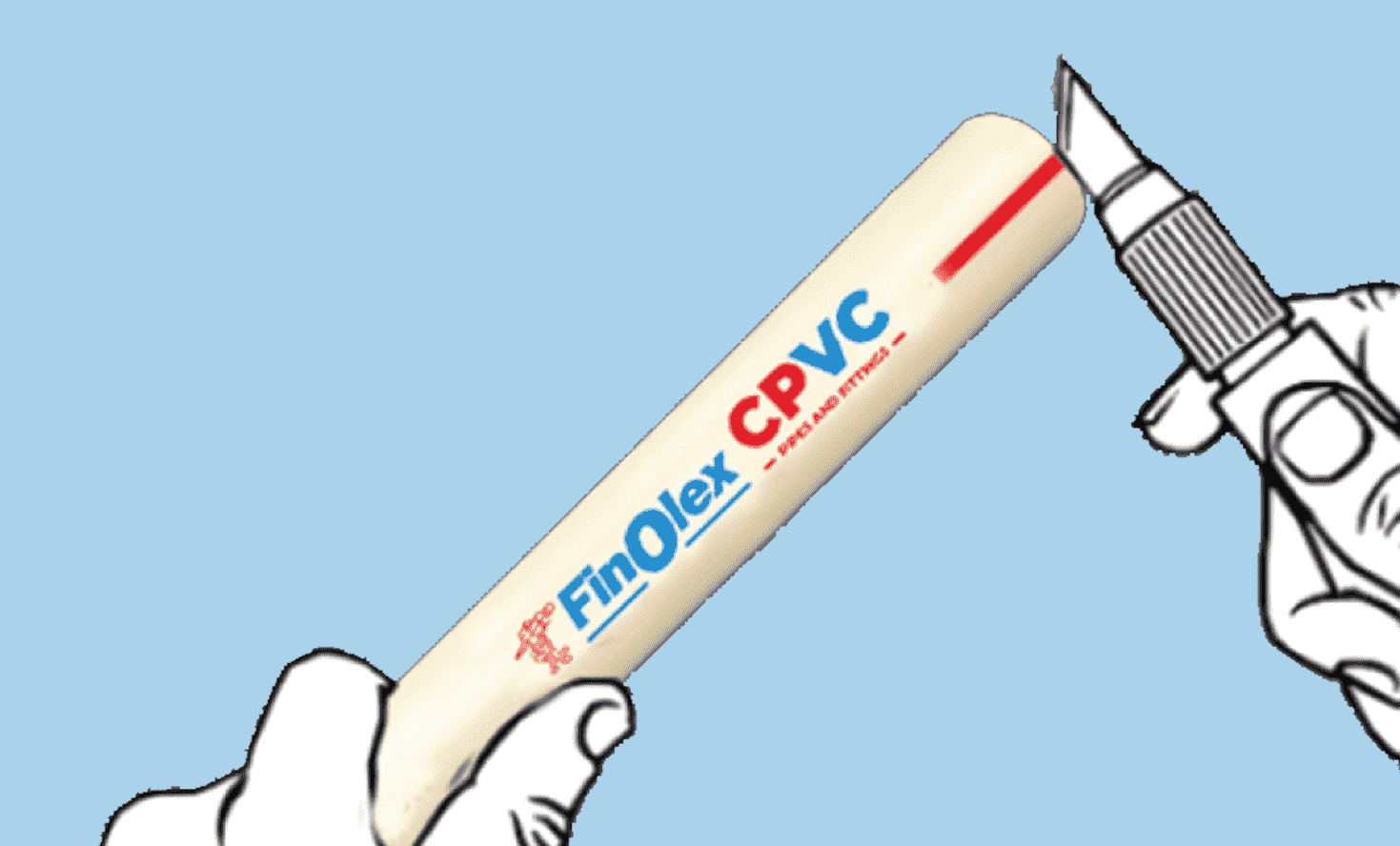

2. Cutting : The pipe must be cut in a square shape. The base of the fitting socket needs a rubber ring to seal it, since an angled cut may result in leakage. |

|

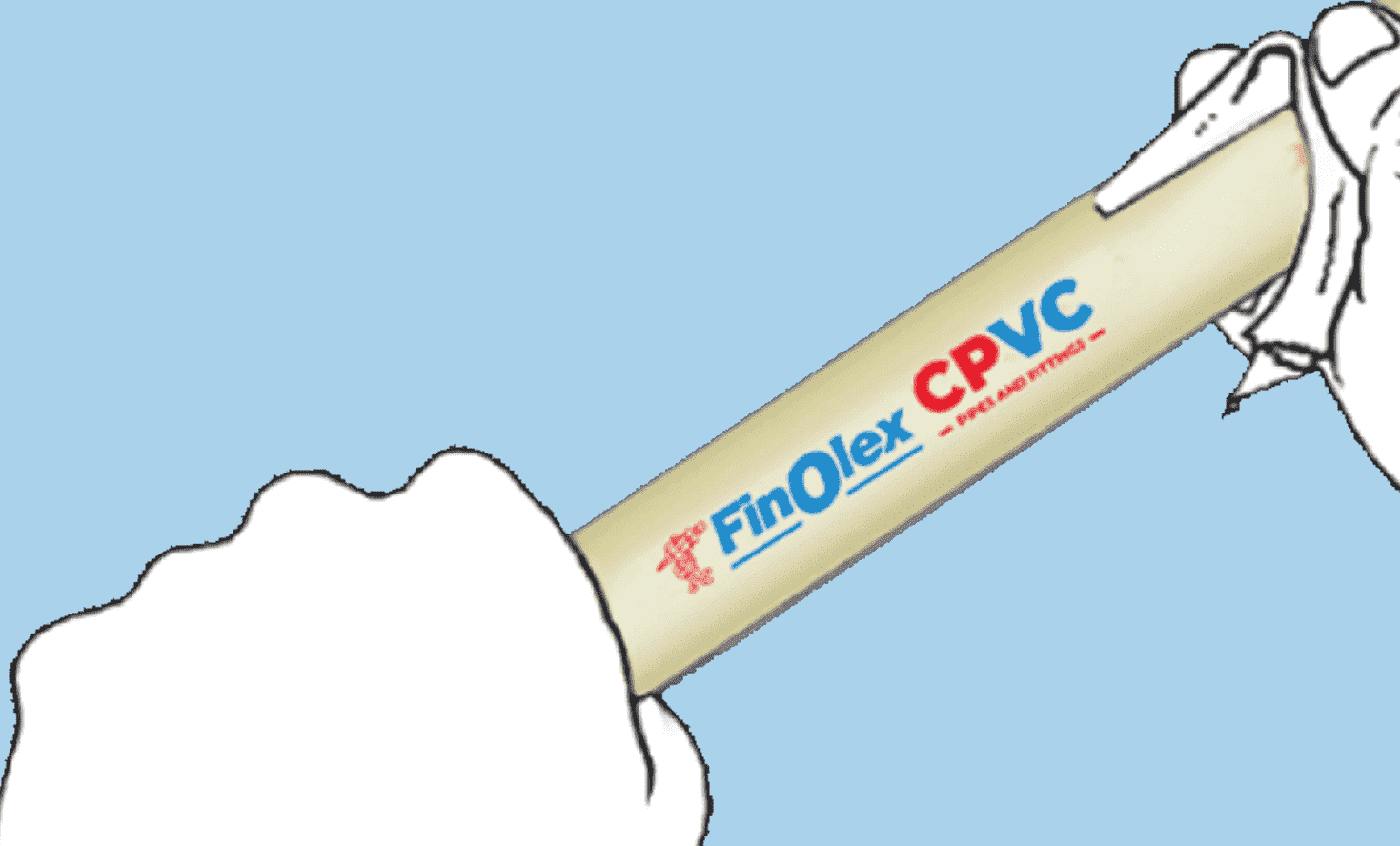

3. Deburring & Chamfering : All the burr must be removed from the inside and outside of the pipe with a knife, file or de-burring tool. A 10° – 15° chamfer must be made at the end of the pipe. |

|

4. Cleaning : The surface dirt, grease or moisture must be removed with a clean dry cloth. |

|

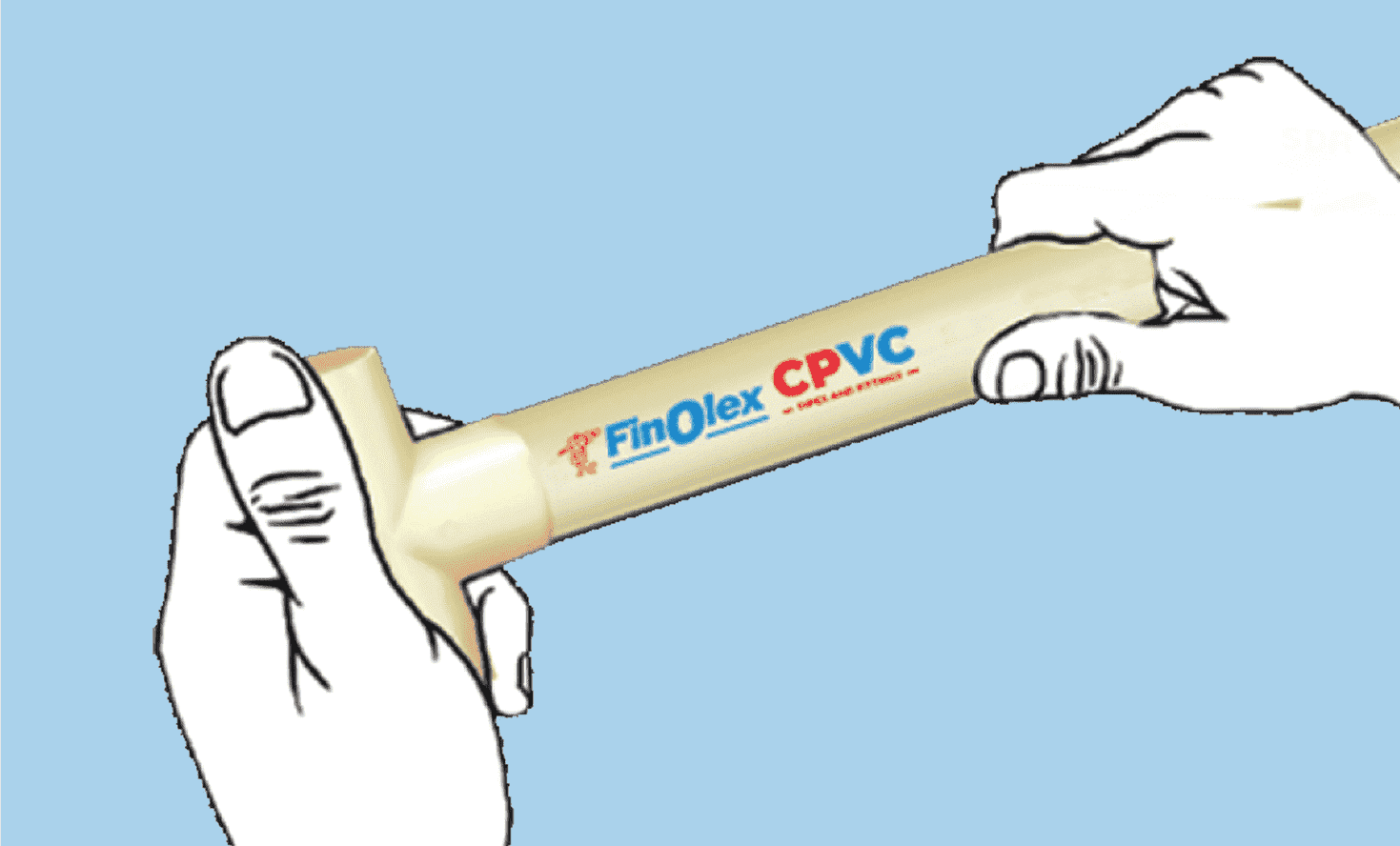

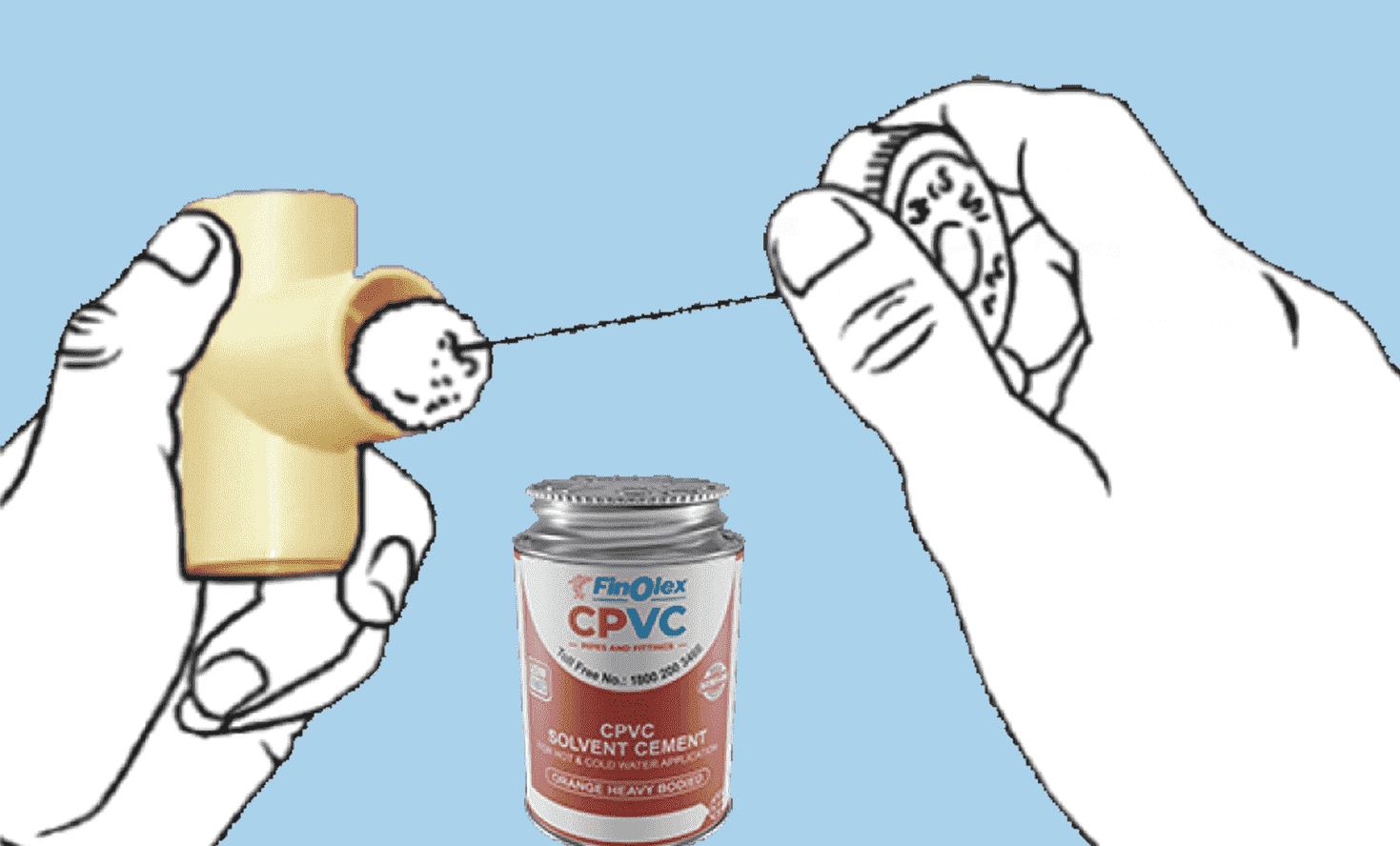

5. Check Dry Fit : Using light pressure, the pipe should be inserted one third to half the way into the socket. Note that pipes and fittings that are too tight or too loose should not be used. |

|

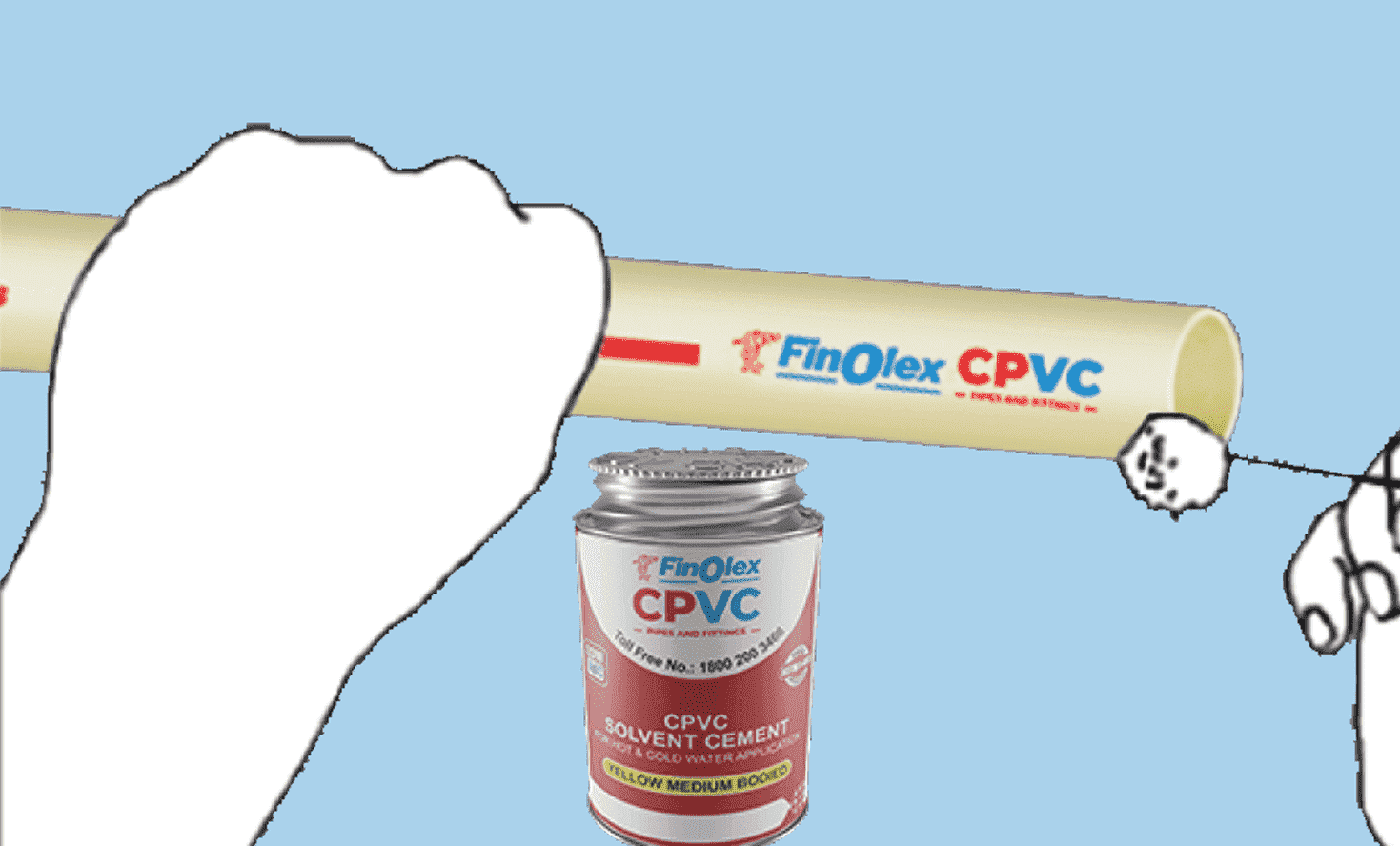

6. Solvent Cement Application : An even layer of cement should be applied to the outer side of the pipe and a medium layer of the plumbing solvent cement to the inside of a fitting. |

|

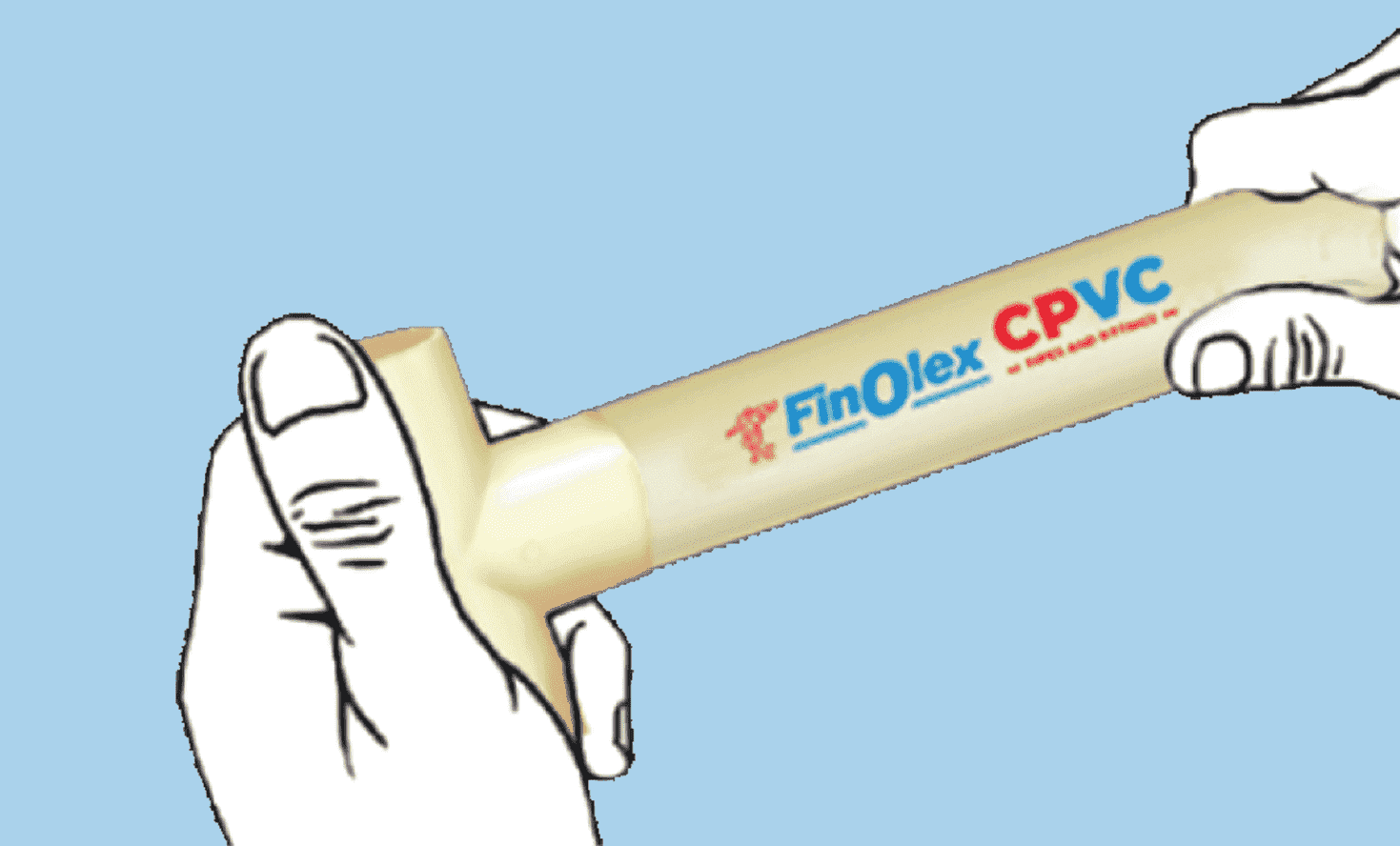

7. Assembly : Join the pipe and fitting socket till in contact with the socket bottom. Hold the pipe and fitting together until the pipe does not retract. The excess cement can be removed from the exterior surface of the pipe and fitting. A properly made joint will show a continuous bead of cement around the perimeter of the pipe and fitting. |

To achieve a perfect joint of pipe and fitting, hold them together for 60 seconds after thoroughly applying solvent cement. Solvent cement requires 10 to 20 minutes for the initial setting. The joint requires a minimum of 24 hours setting time to fully cure. Do not pressure test the pipe until the cement is fully cured or set in position.

SOLVENT SET & CURE SCHEDULE GUIDELINES

AVERAGE INITIAL SET SCHEDULE FOR CPVC SOLVENT CEMENT

Set Schedule is the necessary time to be allowed before the joint can be carefully handled.

(In damp or humid weather allow 50% more set time.)

| Temperature Range | Pipe Sizes | Pipe Sizes | Pipe Sizes |

| Temperature range during assembly and setting period |

½” to 1¼” | 1½” to 2” | 2½” to 6” |

| 16°C to 38°C | 2 minutes | 5 minutes | 30 minutes |

| 5°C to 16°C | 5 minutes | 10 minutes | 2 hours |

| -18°C to 5°C | 10 minutes | 15 minutes | 12 hours |

AVERAGE JOINT CURE SCHEDULE FOR CPVC SOLVENT CEMENT

Joint cure schedule is the necessary time to be allowed before pressurizing the system.

(Allow 50% more set time in damp or humid weather)

| Temperature Range | Pipe Sizes | Pipe Sizes | Pipe Sizes | |||

| Temperature range during assembly and setting period |

½” to 1¼” | 1½” to 2” | 2½” to 6” | |||

| Up to 11 Kg/cm2 |

11 to 22 Kg/cm2 |

Up to 11 Kg/cm2 |

11 to 22 Kg/cm2 |

Up to 11 Kg/cm2 |

11 to 22 Kg/cm2 |

|

| 16°C to 38°C | 15 minutes | 6 hours | 30 minutes | 12 hours | 1- 1½ hours | 24 hours |

| 5°C to 16°C | 20 minutes | 12 hours | 45 minutes | 24 hours | 4 hours | 48 hours |

| -18°C to 5°C | 30 minutes | 48 hours | 1 hour | 96 hours | 72 hours | 8 days |

THERMAL EXPANSION & CONTRACTION

CPVC expands when heated and contracts when cooled, like all piping material. CPVC, regardless of the pipe diameter will expand about 25mm per 15m length (1 inch per 50 feet) in length when put into a 23°C temperature increase; therefore provisions must be made to accommodate this movement. Laboratory testing and installation experience also have demonstrated that the practical issues are much smaller than the coefficient of thermal expansion would suggest. The stress developed in CPVC pipes is generally much smaller than those developed in a metal pipe for the same temperature change, primarily because of the difference in elastic modulus.

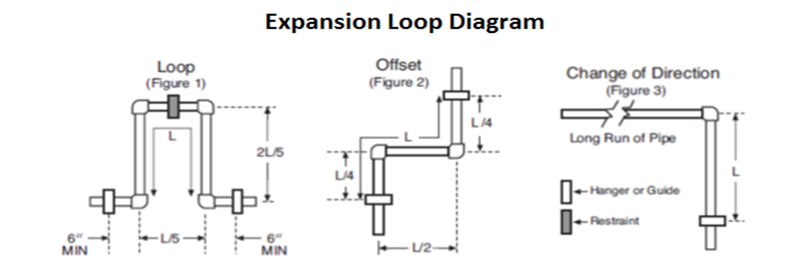

Expansion is mainly a concern in hot water lines. Generally, thermal expansion can be accommodated with changes in the direction. A long straight run may require an offset or loop. Only one expansion loop, properly sized is required in a single straight run, regardless of its total length. If more convenient, two or more smaller expansion loops, properly sized, can be utilised in a single run of the pipe to accommodate the thermal movement. Ensure to hang the pipe with smooth straps that will not restrict the same.

Thermal Expansion Formula:

∆ L = Lp C ∆T

Where

∆L = Change in length due to change in temperature , Lp = Length of pipe

C = Coefficient of Thermal Expansion

CPVC

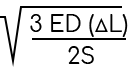

Expansion Loop Formula:

L =

Where

L = Loop in Length (in.), E = Modulus of Elasticity at maximum temperature (psi),

S = Working Stress at Maximum Temperature (psi), D = Outside Diameter of pipe (in.),

∆L = Change in length due to change in temperature (in.).

FINOLEX SOLVENT CEMENT & PRIMER

1) Yellow Medium Bodied (Up to 2”) CPVC SOLVENT CEMENT

CPVC Solvent Cement for Hot & Cold Water plumbing applications

Yellow Medium Bodied (Up to 2”) (Meets ASTM F 493 standard)

| ml | 59 | 118 | 237 | 473 | 946 |

| Container | Tin | Tin | Tin | Tin | Tin |

2) Orange Heavy Bodied (Above 2”) CPVC Solvent Cement

CPVC Solvent Cement for Hot & Cold Water plumbing applications

Orange Heavy Bodied (Above 2”) (Meets ASTM F 493 standard)

| ml | 118 | 237 | 473 |

| Container | Tin | Tin | Tin |

3) Primer for PVC-U plumbing applications (Meets ASTM F 656)

| ml | 237 |

| Container | Tin |

PRECAUTIONS

• Brush must be clean and dry before commencing the solvent welding process.

• When the system is to be concealed, it should be pressure tested before the concealment.

• Do not attempt cementing in the rain or in the presence of moisture.

• The cement should be used within the expiry period mentioned on the container.

• Use of primer prior to the solvent cement joint is essential for pipe sizes 65mm (2 1/2”) and above. This will increase the joint strength.

• Keep cement away from all sources of ignition, heat, sparks and open flame.

• Keep containers of cement tightly closed after use.

• Store solvent cements and piping component in a cool area.

Additional information

DO'S

• Use pipes, fittings and solvent cements manufactured by Finolex Industries for best results.

• Installation should be completed as per instructions and recommended safe practices must be followed.

• Clean the pipe and fittings with a clean dry cloth to remove any dirt.

• Keep pipe and fittings in the original packaging until needed.

• In case any crack is found in the pipe, cut a minimum of 25mm length beyond the edge of the crack.

• Cut the pipe as square or perpendicular as possible before making a joint.

• Ensure no sharp edges are in contact with the fittings surface while inserting the pipe.

• Ensure proper alignment of pipe and fittings to avoid stress on the joints.

• Ensure installation is done in such a way that there are no chances of air entrapment.

• Use only teflon tape as a thread sealant.

• Always conduct hydraulic pressure testing after installation to detect any leaks and faults.

• Wait for the appropriate cure time before pressure testing. Fill lines slowly and allow air to escape from the system prior to pressure testing.

• Paint pipes exposed to sunlight with a water-based paint.

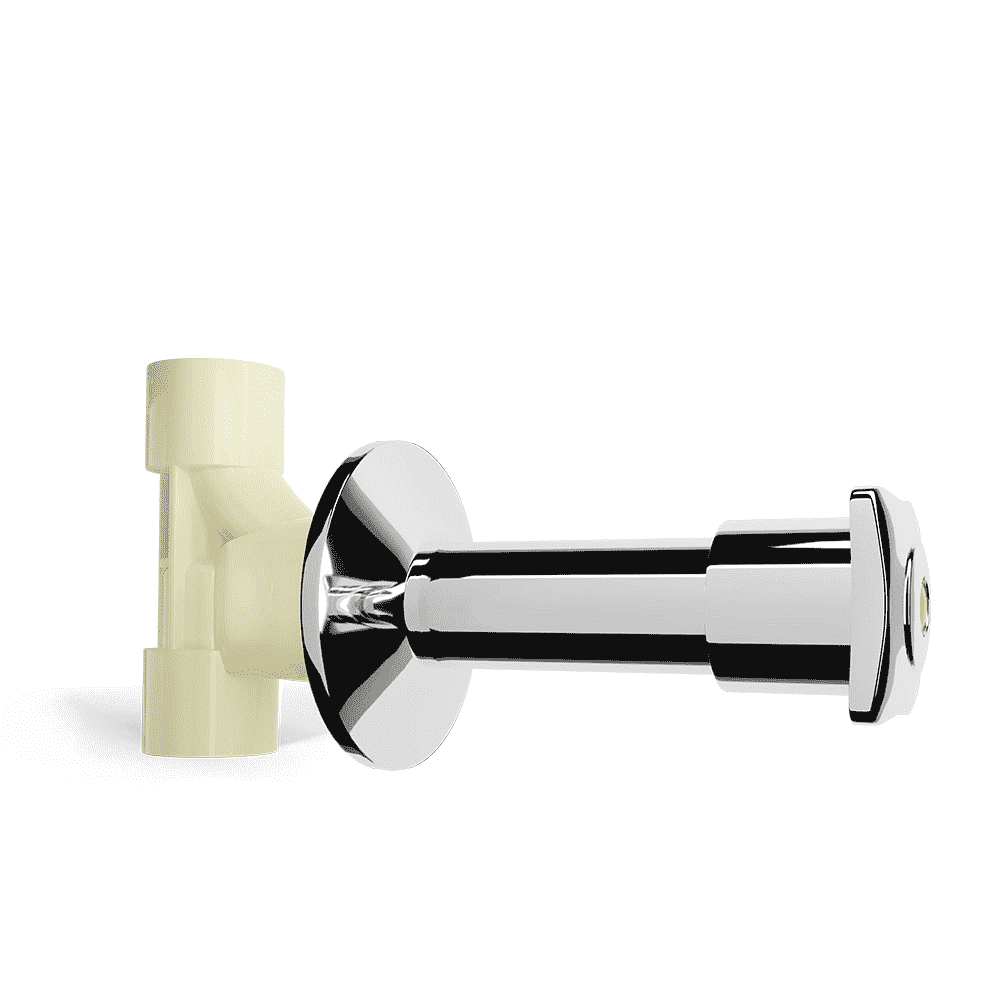

• Provide additional support to the brass side of CPVC/brass transition or other for keeping any heavy object to support the weight of the metal system.

DON'TS

• Do not use metal hooks or nails to support/hold or put pressure on the pipes.

• Do not use straps and hangers with rough or sharp edges. Do not tighten the straps over the pipes.

• Never expose the pipe to open flame while trying to bend it.

• Do not drop pipes on edges from heights. Do not drop heavy objects on pipes or walk on pipes.

• Do not use air or gases for pressure testing.

• Do not use any other petroleum or solvent-based sealant, adhesive, lubricant or fire-stop material on CPVC pipes & fittings.

• Do not use CPVC pipes and fittings for pneumatic applications.

• Do not use the CPVC piping system to support any metallic components.

• Do not use CPVC solvent cement that exceeds its shelf life, has become discoloured or has gelled.

INSTALLATION OF CPVC PIPES WITH SOLAR WATER HEATERS

• SDR 11 pipes are recommended for use with solar water heaters in the main line.

• Based on the height of the building, it is necessary to provide expansion and contraction loops in

case of exposed piping used in solar water heater installations.

• It is strongly recommended that solar water heaters must be installed with thermo-regulating valves. However, if

thermo-regulating valves are not available, air-venting on the hot water outlet side must be provided.

• Only brass transition fittings must be used for all connections with solar water heaters.

• Ensure that proper support spacing, i.e. pipe clamp supporting, is maintained. At the roof level, in

case proper support is not available against the wall or the floor, bricks should be used to provide

permanent support to the piping.

• When used with gas water heaters, CPVC pipes and fittings should not be directly connected to the

heater. At least 150mm (6”) clearance from the flame is recommended. For the initial portion a long

metal nipple or GI Pipes must be used.

• Finolex CPVC pipes can be directly connected to the electrical water heater with special metal-to -CPVC transition

fittings.

• Don’t thread, groove or drill CPVC pipes.

CERTIFICATIONS & APPROVALS

• Pipes are manufactured conforming to IS 15778 (Bureau of Indian Standards).

• Pipes, fittings comply with ASTM D 2846, ASTM F 441, ASTM F 438 ,ASTM F 439 and Solvent cement comply with ASTM F 493.

• Tested & approved by Central Institute of Plastics Engineering & Technology (CIPET).

• Certified by Central Food Technological Research Institute, Mysore (CFTRI).

FAQs

-

What is the range of Finolex CPVC pipes ?

Finolex CPVC plumbing pipes are available in sizes ranging from 15mm (1/2") to 50mm (2"), which conforms to IS 15778 in SDR 11 and 13.5 classes in 'Copper Tube Size' (CTS). Finolex CPVC pipes are also available in ‘Iron Pipe Size’ (IPS) ranging from 65mm (2 1/2") to 150mm (6") in Schedule 40 and Schedule 80 series, which meet the requirements of ASTM F 441. For more information refer to the Finolex CPVC Pipes and Fittings Brochure.

-

What is the difference between SDR 11 and SDR 13.5 CPVC pipes ?

Standard dimension ratio (SDR ). SDR-11 pipes have more wall thickness and higher pressure ratings than SDR-13.5,for the given size.

-

What is the Finolex range in CPVC fittings?

Finolex CPVC fittings are available from ½” to 2” in SDR 11 (ASTM D 2846)

2 ½” to 4” in SCH 80 (ASTM F 439) and 6” in SCH 40 (ASTM F 438). -

What are the major features and benefits of Finolex CPVC pipes ?

Finolex CPVC pipes are--

a) Lead free thus safe for potable water.

b) UV stabilised , thus ideally suitable for external plumbing applications , as it is not affected by UV rays in the sunlight and is durable & long lasting.

c) Ideal for hot and cold water plumbing applications.

d) Outstanding fire safety profile. Does not support fire.Self-extinguishing and do not support combustion

e) Low thermal conductivity,so water remains hotter for longer duration of time especially as required in hotels, hospitals,as dissipation of heat is slow thus high energy saving.

f) Unaffected by chlorine in water. In India,municipalities or corporations use chlorination treatment for water purification, here the quality of pipe is not affected by chlorine treated water running through the pipeline.

g) No corrosion resulting in uncompromised water quality, as compared to GI pipes.

h) No scaling, pitting or leaching formation , as seen in GI other metallic pipes,reducing the life of GI pipe and also the discharge of water over a period of time.

i) High Mechanical strength,so tough and durable -

Do you have different solvent cement for different CPVC pipes ?

We have Finolex CPVC yellow medium bodied solvent cement for CPVC upto 2”dia.pipes and Finolex orange heavy bodied solvent cement for Finolex CPVC above 2”dia pipes.

-

Can Finolex CPVC pipes be used and exposed to sunlight?

Finolex CPVC pipes are UV stabilised in the manufacturing process itself and hence can be used for all the external plumbing applications. Quality of Finolex CPVC pipes is not affected by exposure to sunlight. However, for such pipes, we recommend to use and paint these pipes by light coloured water-based paint and not oil based paint.

-

What is the normal chlorine % in PVC and CPVC Pipes ?

PVC pipes normally have 57 % chlorine in it, as against , 67 % chlorine in CPVC. This enhanced chlorine % in CPVC, makes it ideal for cold and hot water plumbing applications and it can withstand higher temperatures of running water.

-

What are the key points of CPVC in the CTS series ( ½”to 2 “) ?

CPVC pipes in CTS series ( ½ “ to 2 “), pressure rating for the given temperature remains the same,irrespective of the size of the pipe. In short,even if the OD of the pipe increases say from 1/2 “ to 2 “, the pressure rating for the given temperature, say at 82 degrees celsius, remains the same for the category say SDR 11. It holds true for SDR 13.5 as well.

-

How do I identify CPVC- SDR 11 and SDR 13.5 pipes ?

In CPVC pipes, SDR 11 has higher wall thickness. The colour of the screen /matter printing on the pipe is RED.

SDR 13.5 has less wall thickness than SDR11. The colour of the screen / matter printing on the pipe is BROWN. This is for the ease of identification of pipes on the basis of print colour on the pipe. -

What precautions should be taken for CPVC while using it for gas geysers and electric water heaters and solar water heaters ?

• CPVC Installation- Only brass transition fittings must be used for all connections with solar water heaters.

• Ensure that proper pipe clamp support is provided.

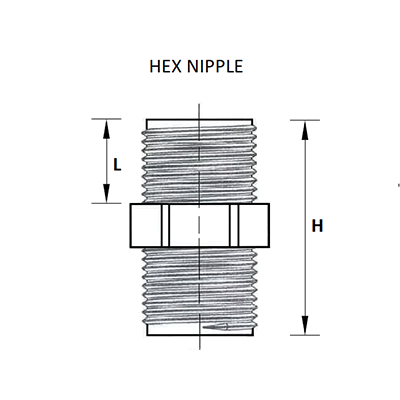

• When used with gas water heaters, CPVC pipes and fittings should not be directly connected to the heater. At least 150mm (6”) clearance from the flame is recommended. For the initial portion a long metal nipple or GI pipes must be used.

• Finolex CPVC pipes can be directly connected to the electrical water heater with special metal-to-CPVC transition fittings. -

Occasionally, why do we observe CPVC pipe bulging near the cold water inlet of the geyser ?

CPVC Bulging near the cold water inlet could be probably due to the malfunctioning or non-functioning of the thermostat in the geyser, resulting in sudden increase of water temperature leading to steam formation. This steam tries to escape out of the system, Due to negative pressure created in the system, this steam gets diverted to cold water inlet and tries to escape, leading to bulging of cpvc pipe there. CPVC pipe takes the entire brunt / pressure of the generated steam,by just bulging , but in the process, saves the geyser from possible bursting.

Now, please note that here, in place of CPVC , if GI pipe was there, then entire steam pressure would have come on geyser ,which in all probabilities, would have led to bursting of geyser. -

What is the maximum recommended working temperature for the Finolex CPVC piping system?

Finolex CPVC piping systems are recommended to be used upto 82 deg.Celsius at max pressure of 6.93 and 5.6 Kg/cm2 for SDR 11 & SDR13.5 Respectively for sizes from ½” to 2”.

-

What are the common applications of the Finolex CPVC Piping system?

Finolex CPVC piping system is recommended for hot and cold water plumbing applications in residential and commercial establishments,hotel and resorts, hospitals,high and low rise buildings, corporate offices, swimming pools,academic institutes, manufacturing plants etc. These pipes are not recommended for compressed air and gas applications.