PVC Pipes For Agriculture

PVC-U AGRICULTURE PIPES & FITTINGS

PVC PIPES FOR AGRICULTURE

Finolex offers an extensive range of agriculture PVC-U pressure pipes and fittings. These pipes and fittings are designed specifically for varied pressure and gravity flow applications in agriculture, irrigation, swimming pool applications, and domestic water supply including potable water supply.

Finolex agriculture PVC-U pressure pipes offer significant advantages. They are light in weight, easy for transportation and installation, and have a high flow rate. High resistance to chemicals and corrosion ensures an extended product life.

Stringent quality assurance approach across all stages of manufacturing gives the product a high degree of reliability, making Finolex agriculture PVC pipes a preferred choice for farmers, government institutions, domestic and commercial establishments and quality conscious people across the country.

Our agriculture pipes and fittings are recommended for water temperatures ranging from 1°C to 45°C. As the usage temperature increases, the strength of the pipes reduces along with the working pressure.Occasional rise in temperatures in the summer with concurrent reduction in temperature during nights has no adverse effect on the working pressure of pipes.

Finolex agriculture PVC-U pipes are manufactured in a wide range of sizes and pressure classes conforming to standard IS 4985:2000. These agriculture water pipes are available in sizes ranging from 20 to 400 mm in different pressure classes. They are available in two types of joints, Selfit (solvent cement joint) and Ringfit (rubber ring joint).

PVC - U AGRICULTURE - SELFIT PIPE

Conforming to IS 4985

One end of the Selfit pipe is self-socketed and the other is plain. The snug fit of one pipe into the other due to the self-socketed and plain pipe fitment and solvent cement application, eliminates the use of any couplers.

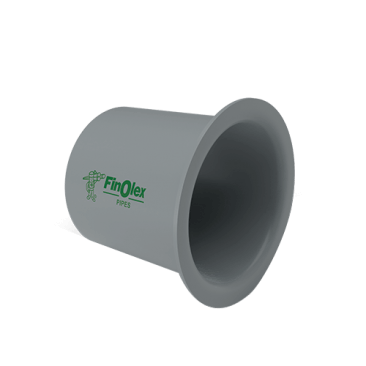

PVC - U AGRICULTURE - RINGFIT PIPE

Conforming to IS 4985

Finolex Industries introduced this unique range of PVC-U pipes for the first time in India. These pipes are especially designed for higher diameter requirements and eliminates the need for solvent cement. The range includes sizes from 63 mm to 400 mm diameter; in 2.5,4,6,8, 10 and 12.5 kgf/cm2 working pressure classes.

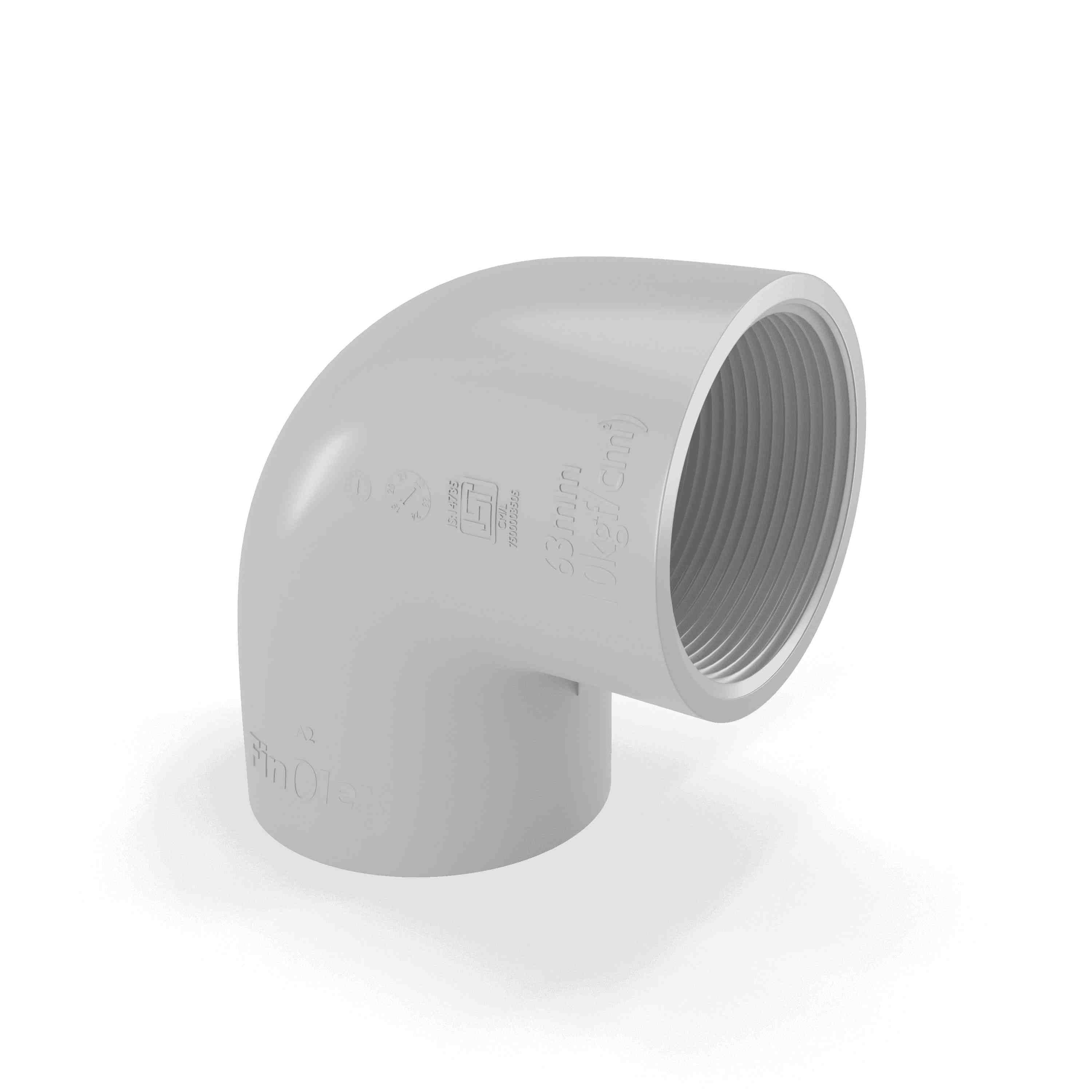

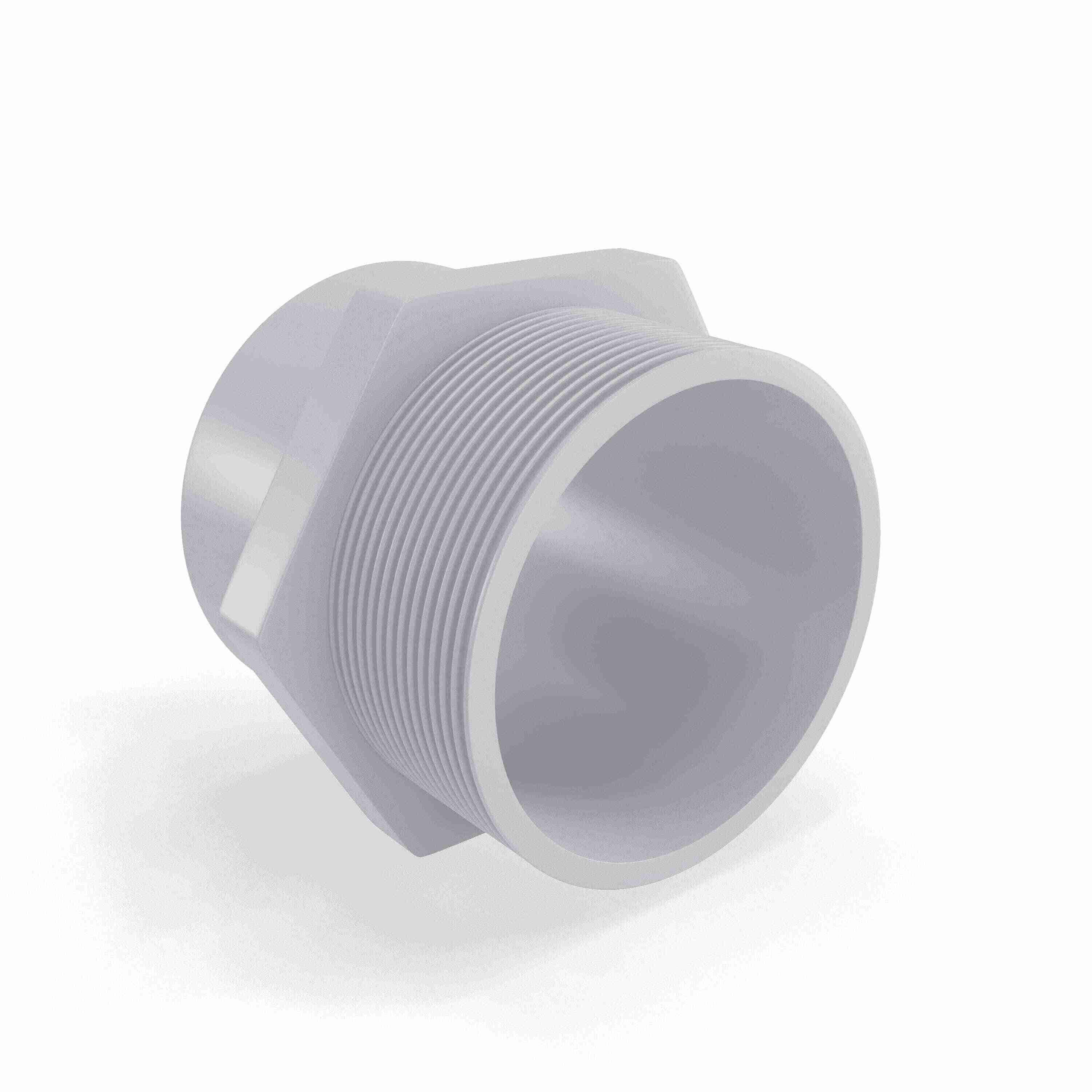

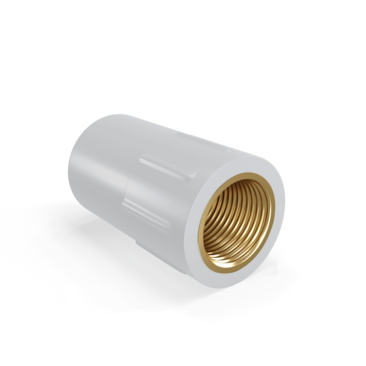

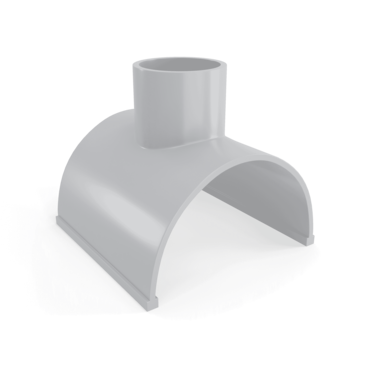

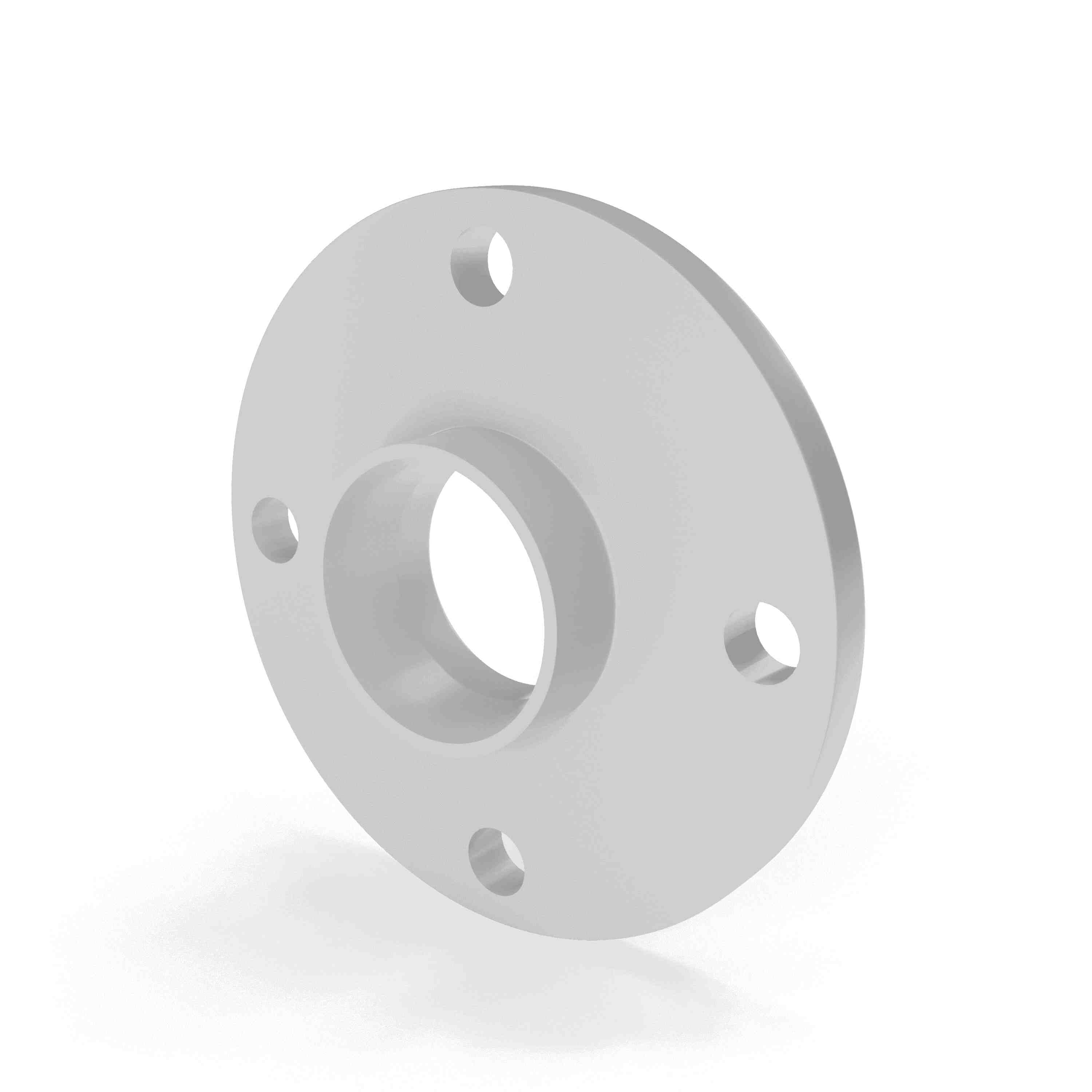

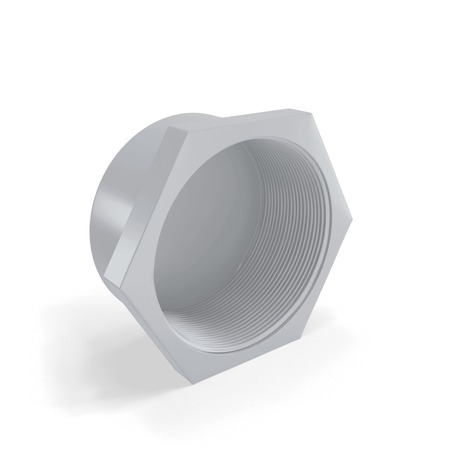

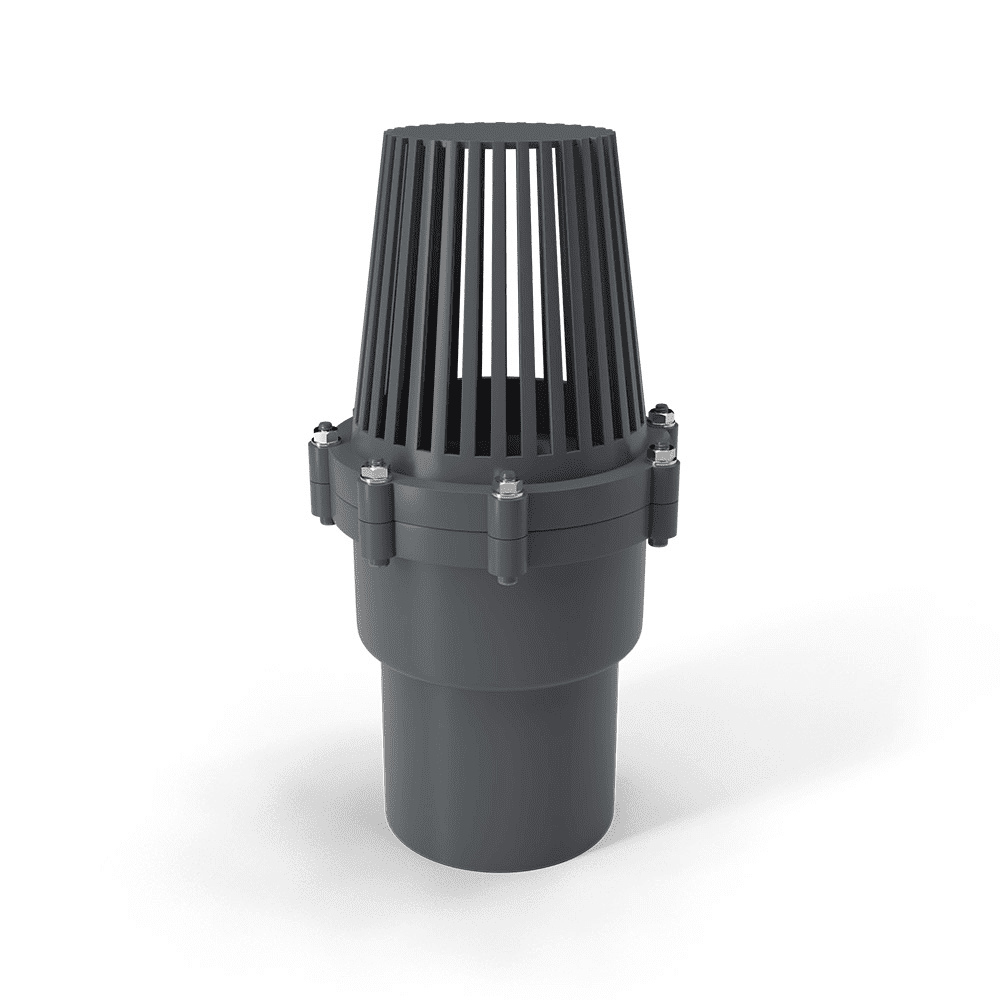

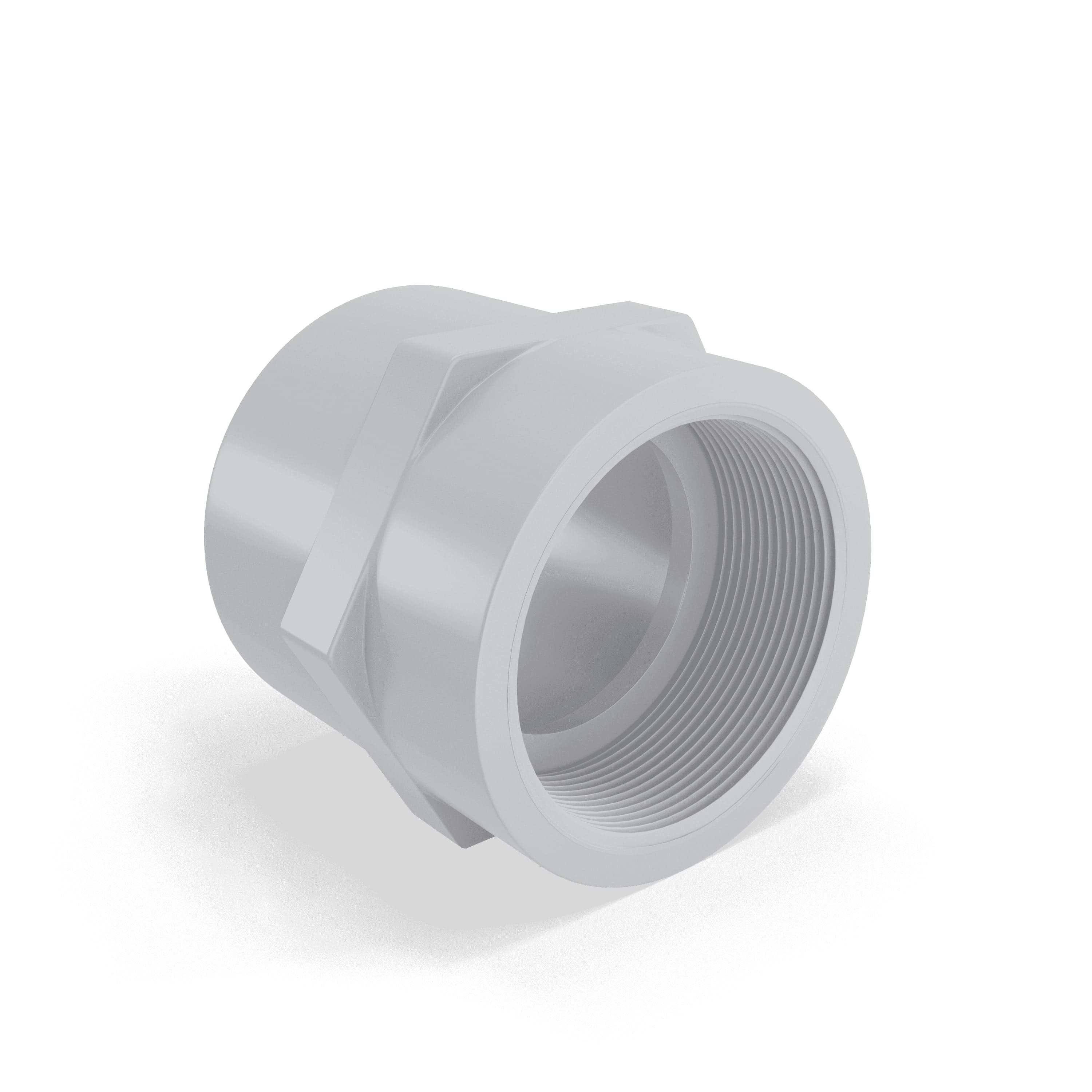

PVC FITTINGS (Moulded & Fabricated)

A wide range of moulded fitting manufactured as per the IS 7834 standards are available. We also manufactured fabricated fittings.

Fittings

MOULDED FITTINGS

FABRICATED FITTINGS

Applications

PVC-U pipes are used for efficient transportation of water in agriculture and allied applications like:

Technical Details

JOINTING

For Ringfit Pipes :

|

1. Cleaning : The surface dirt, grease or moisture must be removed with a clean dry cloth. |

|

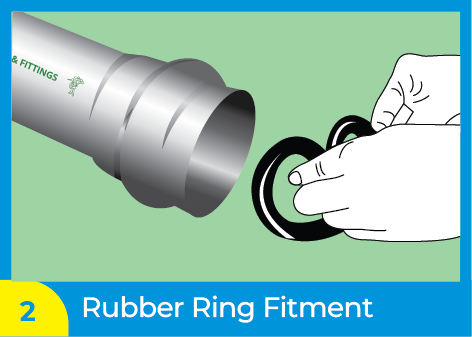

2. Rubber Ring fitment : Take rubber ring & clean for surface dirt of any & insert in pipe groove by hand. |

|

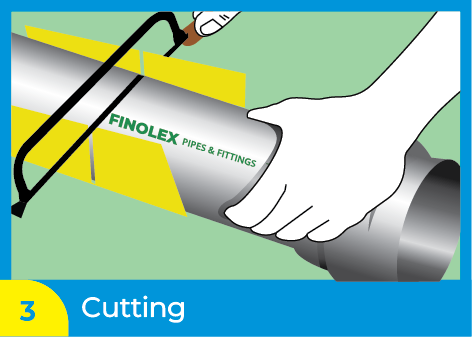

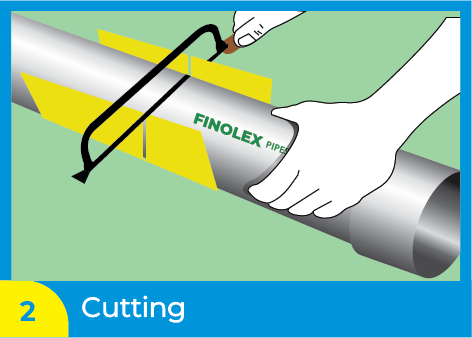

3. Cutting : The pipe must be cut in a square shape. The base of the fitting socket needs a rubber ring to seal it, since an angled cut may result in leakage. |

|

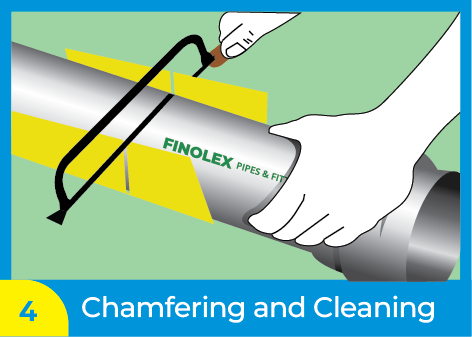

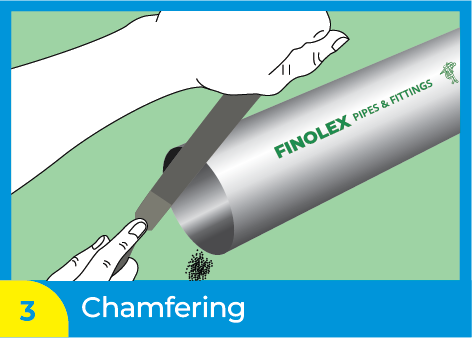

4. Chamfering and cleaning : The surface dirt, grease or moisture must be removed with a clean dry cloth. A 10° – 15° chamfer must be made at the end of the pipe. |

|

|

5. Lubricant application : Apply even layer of lubricant on rubber ring and outer diameter of pipe prior to insertion. |

|

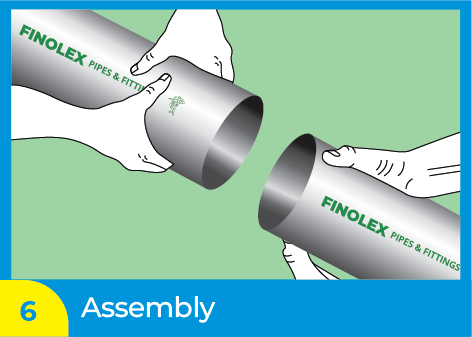

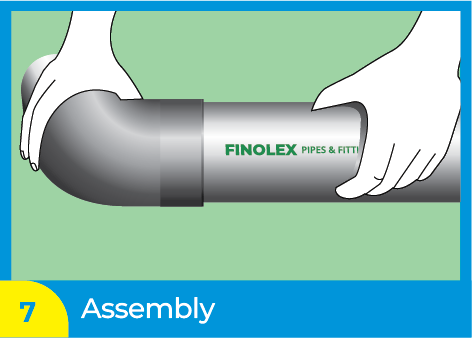

6. Assembly : Push the pipe in integrated ring socket till end. |

For Selfit Pipes & Fittings:

|

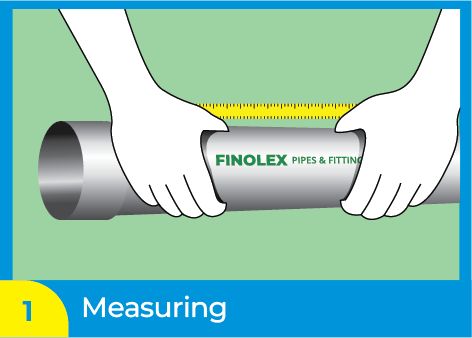

1. Measuring : Measure the required length of pipe and marking done. |

|

2. Cutting : The pipe must be cut in a square shape. The base of the fitting socket needs a rubber ring to seal it, since an angled cut may result in leakage. |

|

3. Deburring & Chamfering : All the burr must be removed from the inside and outside of the pipe with a knife, file or de-burring tool. A 10° – 15° chamfer must be made at the end of the pipe. |

|

4. Cleaning : The surface dirt, grease or moisture must be removed with a clean dry cloth. |

|

5. Check Dry Fit : Using light pressure, the pipe should be inserted one third to half the way into the socket. Note that pipes and fittings that are too tight or too loose should not be used. |

|

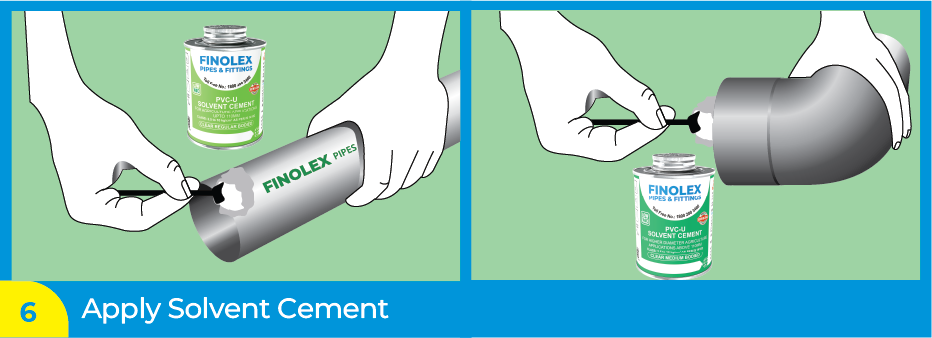

|

6. Solvent Cement Application : An even layer of cement should be applied to the outer side of the pipe and a medium layer of the solvent cement to the inside of a fitting. |

|

7. Assembly : Join the pipe and fitting socket till in contact with the socket bottom. Hold the pipe and fitting together until the pipe does not retract. The excess cement can be removed from the exterior surface of the pipe and fitting. A properly made joint will show a continuous bead of cement around the perimeter of the pipe and fitting. |

FINOLEX SOLVENT CEMENT & LUBRICANT

1. SOLVENT CEMENT

PVC-U Solvent Cement for agriculture applications up to 110 mm (4”) (As Per IS 14182)

| ml | 100 | 250 | 500 | 1000 | 5000 |

| Container | Tin | Tin | Tin | Tin |

can |

2. RUBBER LUBRICANT

Finolex Agriculture Rubber Lubricant is used for installation of Agriculture pipes and fittings with Rubber ring.

| gms | 50 | 100 | 250 | 500 | 1000 |

| Container | Plastic Container | ||||

3. SOLVENT CEMENT

PVC-U Solvent Cement for high diameter agriculture applications above 110 mm (4”) (As Per IS 14182)

| ml | 250 | 500 | 1000 | 5000 |

| Container | Tin | Tin | Tin | can |

| Outside diameter of pipe (mm) |

Outside diameter of pipe (inches) |

Approx No. of Joints/Ltr. of Finolex Solvent Cement |

|||

| 20 | ½” | 300 | |||

| 25 | ¾” | 250 | |||

| 32 | 1" | 225 | |||

| 40 | 11/4” | 175 | |||

| 50 | 11/2” | 130 | |||

| 63 | 2” | 125 | |||

| 75 | 21/2” | 100 | |||

| 90 | 3” | 75 | |||

| 110 | 4” | 50 | |||

| 140 | 5” | 35 | |||

| 160 | 6" | 28 | |||

| 180 | 7” | 25 | |||

| 200 | 8” | 15 | |||

| 225 | 9” | 12 | |||

| 250 | 10” | 9 | |||

| 280 | 11” | 7 | |||

| 315 | 12” | 5 | |||

| 355 | 14” | 3 | |||

| 400 | 16” | 2 |

Additional information

1. The pipes should be laid on a firm soft surface.

2. The pipes should never be laid on rocky surfaces and where sharp objects may damage pipes.

3. The pipes are not suitable in waterlogged areas.

4. The pipes should not be laid on stilts, stubbed columns or supports.

5. The ring fit pipes offer the flexibility of movement of 2 degrees in each joint.

6. The pipes should be laid at sufficient depth below the ground to avoid damage due to the movement of heavy vehicles or machines.

CERTIFICATIONS & APPROVALS

• Pipes conform to IS 4985 (Bureau of Indian Standards).

• Fittings manufactured as per IS 7834 (Bureau of Indian Standards).

• Approved and tested by Central Institute of Plastics Engineering and Technology (CIPET).

• Approved and tested by SGS laboratory.

FAQs

-

What are the types of Agriculture Pipes & Fittings?

Agriculture Pipes are available in 02 types. 1. Selfit (Solvent Cement Joint) 2. Ringfit (Rubber Ring Joint).

-

What is the IS Standard for Agriculture range?

Agriculture Pipes are conforming to IS 4985. Agriculture moulded fittings are as per IS 7834.

-

What is the range of Finolex Agriculture pipes?

Finolex manufactures Agriculture water pipes from 20 mm to 400 mm dia pipes in various pressure classes viz- (2.5 ,4,6,8,10,12.5) kg/cm2 .

-

Which is the primary uses of Finolex Agriculture pipes?

Finolex Agriculture PVC pipes are primarily used in agriculture & potable water supply.

-

Which are the key applications of Agriculture Pipes & Fittings?

Agriculture PVC pipes & fittings are used for pressure and gravity flow applications in agriculture, irrigation, potable water supply, and swimming pools.

-

Agriculture pipelines are normally laid down at what depth below the surface?

Agriculture water pipes are normally laid down at a depth of 1 meter below the ground surface, excluding the OD of the pipeline.

-

For the agriculture pipeline scheme, how many pipes of 6 kg/cm2 are recommended from the source of water or pump?

It all depends on the design from your consulting engineer based on the head of the pipeline (static + frictional) and other head losses, water surge/hammer. “L“ section from your engineer will clearly indicate the exact number of 6 kg/cm2 pipes at the beginning of the pipeline.

-

What could be the normal reasons for Agri pipes bursting in an Agri pipeline?

Faulty pipeline design, deviations from the design, wrong pipe size in mm (undersize), High HP motor/pump, insufficient and wrongly placed air valves, and poor-quality PVC pipes and many more, can lead to bursting of pipes in agriculture pipelines.

-

Heavy duty solvent cement for agriculture pipes is used for which sizes?

Heavy duty solvent cement should be used for Agriculture pipes above 110 mm (4“) pipes.

-

For which Agriculture pipes rubber lubricant is used?

Rubber lubricant is used for the installation of Ringfit Agri pipes & fittings.

-

How Agri pipes should be stored?

Agri pipes should be stored on a flat surface, in a crisscross manner, with the socket facing outwards and the height should not exceed 1 meter. Pipes should not be exposed to sunlight.

-

When can the Selfit Agri pipeline be charged?

After joining with solvent cement, a curing time of 24 hours is required and thereafter, the pipeline can be charged/commissioned.