Applications

Enquiry Form

Provide your information, and our team will promptly contact you to address your queries or needs.

Use Finolex Pipes, fittings, and solvent cement for the best results

Follow proper installation instructions and use a clean, dry cloth to remove any dirt

Keep pipes and fittings in their original packaging until needed

Cut the pipe squarely and if there's a crack, cut at least 25mm beyond it

Insert the pipe without sharp edges touching the surface of the fitting and maintain proper alignment to prevent joint stress

After installation, ensure no air is trapped and conduct hydraulic pressure testing to detect leaks and faults

Only use Teflon tape for thread sealing and protect exposed pipes with water-based paint against sunlight

Provide additional support to the brass side of a CPVC/brass transition to support the weight of the metal system

Wait for the appropriate cure time before pressure testing. Fill lines slowly and allow air to escape before testing

Avoid using metal hooks or nails to support or put pressure on pipes

Use straps and hangers without rough or sharp edges, and avoid tightening them over pipes

Never expose pipes to an open flame when trying to bend them

Avoid dropping pipes from heights or placing heavy objects on them

Do not use air or gases for pressure testing

Avoid using petroleum or solvent-based sealants, adhesives, lubricants, or fire-stop materials on CPVC pipes and fittings

Do not use CPVC pipe fittings for pneumatic applications

Do not use the CPVC piping system to support metallic components

Do not use CPVC solvent cement that has exceeded its shelf life, is discoloured, or gelled

The range of Finolex CPVC pipes includes various sizes and types to cater to different plumbing needs. For more information refer to the Finolex .

SDR 11 CPVC pipes have a higher pressure rating than SDR 13.5 CPVC pipes, indicating their suitability for higher-pressure applications.

The Finolex range in CPVC fittings includes a wide variety of fittings like couplers, elbows, tees, reducers, etc.

Major features and benefits of Finolex CPVC pipes include high strength, durability, corrosion resistance, thermal resistance, and easy installation.

Yes, Finolex offers different solvent cement for different types of CPVC pipes.

Finolex CPVC pipes are designed to withstand long-term exposure to sunlight without any degradation.

The normal chlorine % in PVC pipes is 57% whereas in CPVC pipes it is 63%.

Key points of CPVC in the CTS series include its suitability for hot and cold water applications, corrosion resistance, and easy installation.

CPVC-SDR 11 pipes can be identified by their Yellow colour, while CPVC-SDR 13.5 pipes are Light Grey.

Precautions like using proper support and expansion loops should be taken while using CPVC for gas geysers and water heaters to prevent pipe bulging.

Occasionally, CPVC pipe bulging near the cold water inlet of the geyser can be observed due to expansion and contraction of pipes with temperature changes.

The maximum recommended working temperature for the Finolex CPVC piping system is 82 degrees Celsius (180 degrees Fahrenheit).

The common applications of the Finolex CPVC piping system include residential plumbing, commercial buildings, water distribution, and industrial applications.

CPVC pipes are chosen for household plumbing material due to their corrosion resistance, chemical resistance, durability, and ease of installation.

The expected lifespan of CPVC pipes is around 50-70 years, depending on usage and maintenance.

Yes, CPVC pipes and fittings are highly resistant to chlorine.

CPVC is superior to materials like copper, galvanised iron, and PVC in terms of corrosion resistance, durability, and ease of installation.

The main difference between CPVC and PVC is that CPVC can withstand higher temperatures and has better chemical resistance.

CPVC pipes and fittings are suitable for a wide range of applications including hot and cold water supply, industrial processing, irrigation, and fire sprinkler systems.

Here are a few tips to keep in mind when installing CPVC pipes with solar water heaters:

CPVC pipes expand when heated and contract when cooled. The expansion is approximately 25mm per 15m length (1 inch per 50 feet) for a 23°C temperature increase. It is important to plan for this movement by making provisions during installation. However, laboratory testing and real-world experience have shown that the practical issues related to expansion are smaller than the coefficient of thermal expansion suggests. CPVC pipes experience lower stress compared to metal pipes due to differences in elastic modulus.

Expansion is a greater concern in hot water lines. To accommodate thermal expansion, changes in direction can be made. For long straight runs, an offset or loop may be necessary. A single properly sized expansion loop is sufficient for a straight run, regardless of its length. If more convenient, multiple smaller expansion loops can be used. It is important to hang the pipe using smooth straps that don't restrict movement.

Thermal Expansion Formula:

∆ L = Lp C ∆T

Where

∆L = Change in length due to change in temperature, Lp = Length of pipe

C = Coefficient of Thermal Expansion

CPVC

Expansion Loop Formula:

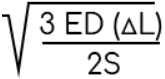

L =

Where

L = Loop in Length (in.), E = Modulus of Elasticity at maximum temperature (psi),

S = Working Stress at Maximum Temperature (psi), D = Outside Diameter of pipe (in.),

∆L = Change in length due to change in temperature (in.).

1.Yellow Medium Bodied (Up to 2”) CPVC SOLVENT CEMENT

Designed specifically for hot and cold water plumbing applications, this solvent cement is suitable for pipe diameters up to 2" and meets the ASTM F 493 standard.

|

ML |

59 |

118 |

237 |

473 |

946 |

|---|---|---|---|---|---|

|

Container |

Tin |

Tin |

Tin |

Tin |

Tin |

2.Orange Heavy Bodied (Above 2”) CPVC Solvent Cement

Our Orange Heavy Bodied CPVC Solvent Cement is perfect for hot and cold water plumbing. Designed for pipe diameters above 2", this solvent cement meets the ASTM F 493 standard to ensure top quality and performance.

|

ML |

118 |

237 |

473 |

|

Container |

Tin |

Tin |

Tin |

3.Primer for PVC-U plumbing applications (Meets ASTM F 656)

This primer is specifically designed for use with PVC-U and CPVC pipes and fittings of all sizes and classes, making it the ideal choice for your plumbing needs.

|

ML |

237 |

|

Container |

Tin |